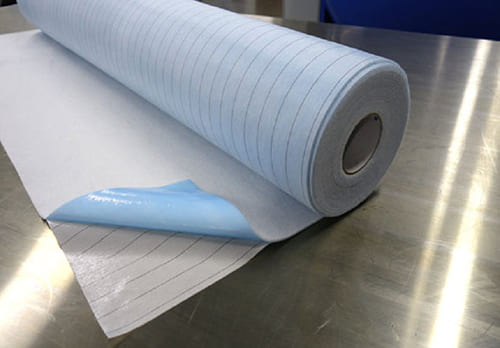

Release fabrics / Peel plies

A Peel Ply is a fabric layer applied on the surface of a composite laminate that can be removed once the composite has cured, leaving a textured surface on the laminate's surface. This is excellent preparation for parts that are to be bonded or painted subsequently.

Release Fabrics are PTFE coated fiberglass fabrics that enable good release in all regularly used resin systems. Non-porous release textiles will easily release from cured laminates and leave a high gloss smooth finish. Porous products allow excess resin, volatiles, and trapped air to escape into the breather during cure, resulting in a textured surface.

Airtech provides the most comprehensive selection of peel plies and release fabrics for multiple layup techniques at different temperatures, available in a variety of widths and at the most competitive prices. The selection of peel ply is determined by how easily a peel ply will release from a surface, which can be used for a unique layup process, which may be best for secondary bonding, what is the material's temperature range, durability, porosity, and general ease of use.

Release fabrics, also known as peel plies, are widely used in the composites industry to achieve consistent surface finishes and bondable surfaces. Airtech offers a large range of peel plies and release fabrics for multiple processes at different temperatures, supplied in different weaves and weights.

Our Release Fabrics/Peel Plies are suitable for use in different resin system temperatures.The useof Release fabrics/peel plies leaves a clean surfaceready for painting and, in most cases, bonding. Customers can select Nylon or Polyester peel plies, either uncoated or silicone-coated for easy release.

For the most challenging applications, Airtech offers Release Ease PTFE coated fiberglass fabrics. Release Ease Release fabrics will release easily from chemically aggressive resins and are useful at very high temperatures.