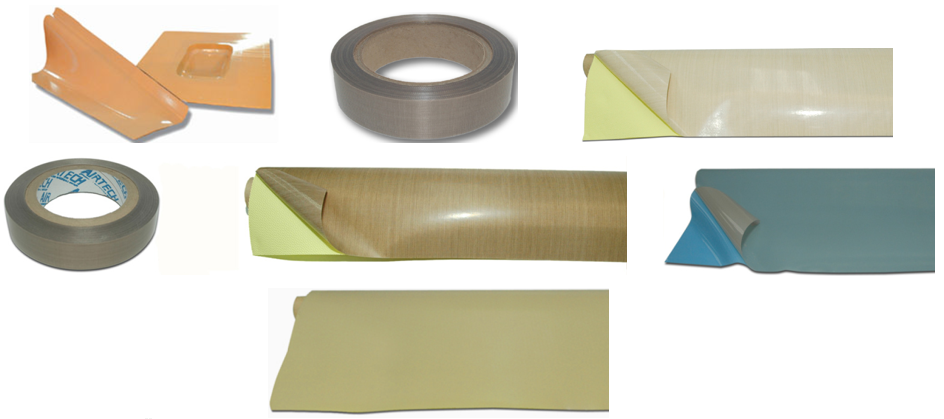

Mold Releases (Non-Liquid)

Mold release is used for a variety of reasons, including keeping the cosmetic tooling surface lustrous, sealing the molds surface, allowing the molds surface to release molded parts, and cleaning the molds surface. Furthermore, polishing products such as buffing pads and buffing equipment are available. These products come in a variety of forms, ranging from basic wax to more sophisticated semi-permanent releasing agents.

With our skilled technical advice, we help customers enhance molding efficiency and achieve their goals using customized release agents tailored to unique materials and applications.

Traditional liquid mold releases involve application of solvent or waterborne releases to tools prior to layup. The use of liquid mold release requires a well-ventilated area outside the clean room with proper PPE.This sometimes involves ovens as well to cure the sealers and release agents.

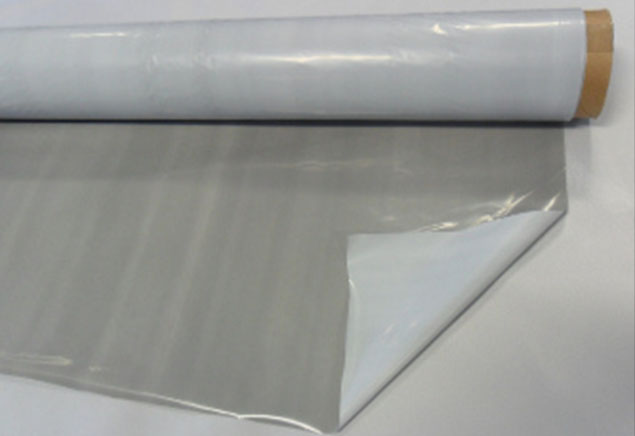

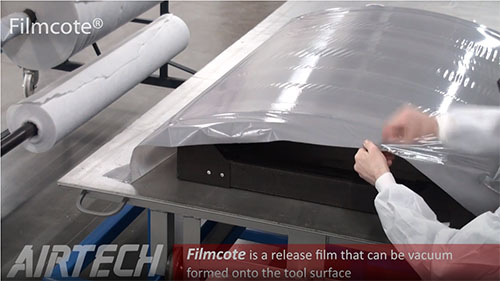

In some cases, for very large tools, autoclaves are used to cure release agents, and this cuts into available autoclave time that could be better used to cure parts.Often,these liquid mold releases are problematic for EH&S reasons. Airtech has developed a range of specialty mold release films designed for direct application to the layup toolsto save labor and processing time.

Airtech’s Tooltec, and Toolwright are semi-permanent mold release films that can be left on the tool surface to support multiple cure cycles, whereas our single use Filmcoteprotects the cured part through subsequent post processing operations. With no drying time and the ability to apply these Mold Release films in the clean room, this increases throughput in the composite shop.