Bagging Films

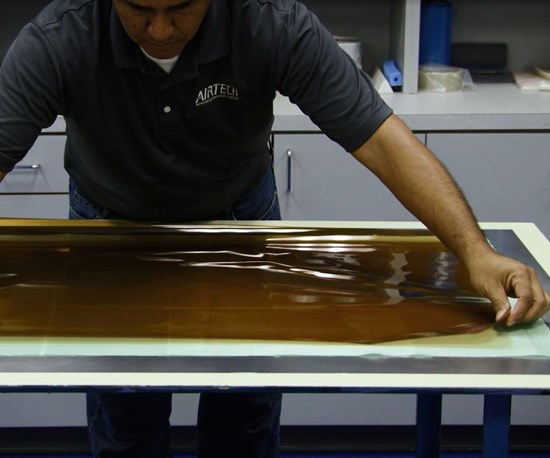

Bagging Films are used to seal and apply uniform pressure to the laminate and tooling surface and applied to ensure compaction, eliminate voids, and extract volatiles.

In choosing a bagging film, we recommend consulting the Airtech Resin Compatibility Guide.

Airtech provides high-performance bagging films with qualities such as welded broad format or customized shapes to save expenses to assure cleanliness, durability, and reliability. Bagging film materials are essential for the success of closed molding, vacuum bagging, and out-of-autoclave processes in the manufacturing of components.

We strive to provide customers with unique solutions through our research and development capabilities. Airtech's research and development capability is focused on unique customer solutions. If you need humidity resistance or customized formatting to reduce labor costs, we are here to help.

Vacuum bagging is a critical operation in the manufacture of any composite or bonded structure, from sporting goods to boats, wind blades to aircraft structures.

Bagging films are used to create high quality composite and bonded structures by applying external pressure on the part, and at the same time removing air and volatiles that can cause voids or porosity in bond lines and laminates.

Airtech has produced bagging films for over 50 years and amassed tremendous experience in materials and the manufacture of films for every application that requires vacuum bagging. From room temperature application to 365°F (204°C) to 752°F (400°C), oven cure, press cure, and autoclave, Airtech has the bagging film that will suit your needs.